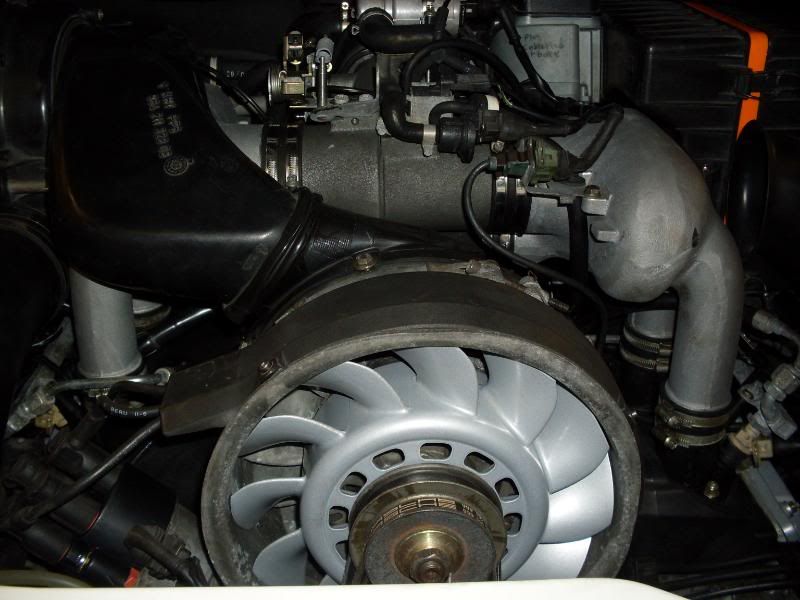

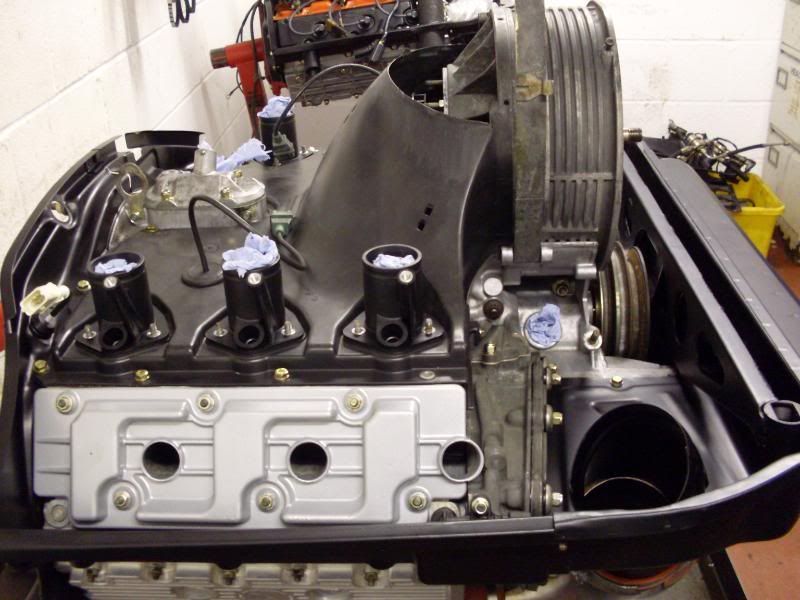

First job was to get the seats out, remove the carpet and everything else in the foot wells. I could then get to work on making a template from cardboard before breaking out the jigsaw on some 6 mm plywood. That was followed by a good coating of yacht varnish:

Here's a piece of the old soundproofing next to one of the new floorboards. The sound proofing pieces weighed 3.5 Kg each and the replacement boards just 2 Kg each:

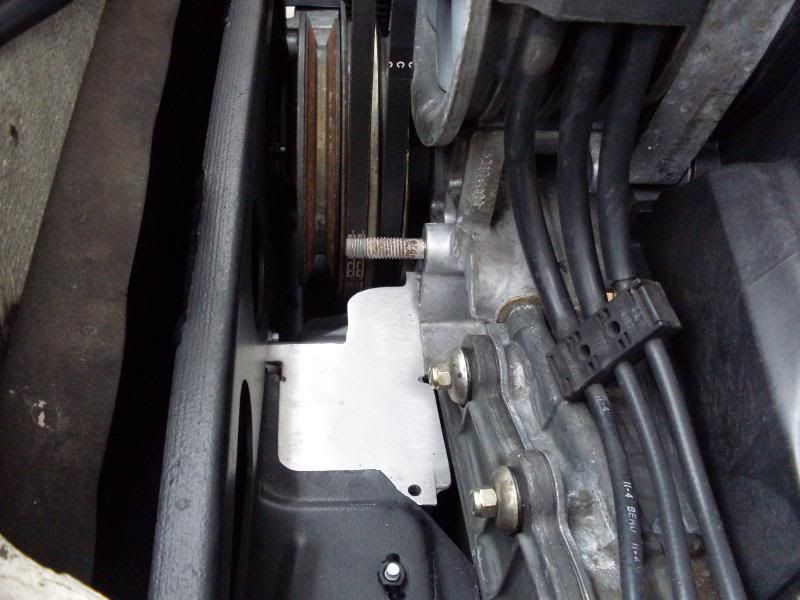

Whilst the boards would be screwed onto the raised beams in the footwell, they also needed to have a support in the deep part. So I came up with a door stop, some repair washers as spacers and bolted these to the boards using one of those two piece bolts that are used to join kitchen units together:

To fit the boards I simply unscrewed the press stud (you can see it just forward of the seat) and then drilled another hole in that same floor beam nearer the pedal box. Then I just used a couple of self-tapping screws and washers to fix the boards in place. Nb. The door stop was located on each board so that it settled on the slightly raised part of the floor (again see pic below).

Passenger floor board fitted:

Driver's side:

Here's my new co-driver checking out one of the seats while it was out of the car!

Of course, it's possible to buy even lighter ready made floor boards (Rennline make them) but since they're optimized for LHD cars, I wasn't sure if they would fit my RHD car. Besides which, the total cost of making my own was less than 20 quid.

The floorboards generated a lot of interest on the 964 Rennlist forum which lead to one of the guys (Thomas from Sweden) sorting out some replica cup car brackets (to replace the doorstop foot) and washers. So I subseqently (Mar 2011) modified the boards to use these instead:

I decided to glue my brackets in and because I want to keep the carpets I pulled up the carpet and cut a slot in the sound proofing so that I could glue the bracket to the tunnel:

Here's the driver's side bracket in place, complete with a rivnut installed for it to receive the floor board.

Here's the hand tool used to put the rivnuts (popnuts) in the brackets and the raised floorboard.

And here's how the passenger side board looks with the new washers fastening in place.